Home » Oil and Gas » Magnolia Oil Platform

Magnolia Tension Leg Oil Platform - Is It the World's Tallest Structure?

Magnolia Platform: Although only a few hundred feet of the Magnolia Platform is visible above water level, its total height from the bed of the seafloor to the top of the platform is 4,698 feet (1,432 meters). Some people consider it the world's tallest structure. Others define "tallest structure" differently. Image by NOAA Ocean Explorer [1].

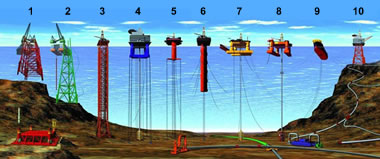

This illustration shows several types of offshore oil and gas structures. Various designs can be used for drilling, production management, crude storage and offloading. #1 and #2 are conventional fixed platforms anchored to the seabed; #3 is a compliant tower; #4 and #5 are vertically moored tension leg and mini-tension leg platforms (#4 represents the design of the ConocoPhillips' Magnolia TLP); #6 is a spar platform; #7 and #8 are semi-submersible platforms; #9 is a floating production, storage, and offloading facility; and, #10 is a sub-sea completion and tie-back to host facility. [4] Image by NOAA. Enlarge.

The World's Tallest Structure?

When the phrase "World's Tallest Structure" is mentioned, most people immediately think of a "skyscraper" or a very tall building. The Burj Khalifa (formerly the Burj Dubai), a skyscraper in Dubai, United Arab Emirates, holds the title of the world's tallest building with an amazing height of 2,717 feet (828 meters).

However, if you consider any structure that extends upwards from Earth's surface, then many deepwater oil platforms are much taller than the Burj Khalifa. In 2009, Guinness World Records recognized an oil platform as the "world's tallest structure."

As of January 1, 2013 the "tallest" oil platform was the Magnolia TLP operated in the Gulf of Mexico by ConocoPhillips. Its total height from the seabed up to the top of platform is 4,698 feet (1,432 meters).

Why Was It Built?

The need for a large deepwater platform in this area was triggered in 1999 when Conoco's ultra-deepwater drillship, the Deepwater Pathfinder, drilled a successful oil well in the Gulf of Mexico. This successful well was drilled in water nearly 5000 feet deep (1,524 meters), about 150 miles (241 kilometers) off the coast of Louisiana. A platform would be needed to manage production from the remote Magnolia oil field, thought to contain about 150 million barrels of oil. The platform was built in South Korea at a cost of about $600,000,000. It was completed in 2004 and towed to the Gulf of Mexico to begin operation.

Ultra-Deep Wells in Ultra-Deep Water

|

The original well drilled by the Deepwater Pathfinder was completed at a depth of 16,868 feet (5,141 meters) below the seafloor. A second well was drilled to a total depth of 17,435 feet (5,314 meters). Although these wells are not counted as part of the Magnolia Platform's height, it creates a total project relief of over 22,000 feet (6,706 meters) from the top of the platform, down to the seabed and then down to the bottom of the production wells.

The Magnolia Offshore Platform is a Busy Place!

The primary function of Magnolia TLP is to manage oil production from five wells drilled into the floor of the Gulf. It has a design capacity of 50,000 barrels of oil per day and 150 million cubic feet of natural gas (4.2 million cubic meters). It currently produces about 5,000 barrels of oil per day. This oil is transported by underwater pipelines to the Shell Enchilada platform which serves as an oil and gas processing and transportation hub.

The Magnolia TLP operates twenty-four hours per day, seven days a week, and 365 days per year. The platform has living quarters, dining facilities and break areas for crew members. They work extended shifts on the platform and are flown to shore by helicopter for off time.

| Magnolia TLP Information |

|

[1] Magnolia Tension Leg Oil Platform, photograph and details, NOAA Ocean Explorer program.

[2] Menck, Contractor for construction of the Magnolia TLP foundation, consisting of eight piles. Hosted on the Internet Archive. [3] Magnolia Deepwater Oil and Gas Field, Gulf of Mexico: information page on the Offshore Technology website, last accessed September 2022. [4] Types of Offshore Oil and Gas Structures, NOAA Ocean Explorer Program. |

The Magnolia TLP (Tension Leg Platform)

One of the most important differences between the Magnolia Platform and a skyscraper is how they are supported. A skyscraper is "held up" by a framework of rigid steel beams and concrete.

The Magnolia platform is a floating structure. Instead of being "held up" it is "held down" by steel tethers connected to the seafloor. This design is known as a "tension leg platform." That is where the commonly used name "Magnolia TLP" originates. This design is quite the opposite of how most people think of a "tall structure."

The "hull" of the Magnolia TLP consists of four cylindrical columns (the yellow cylinders in the photo at the top of this page). These columns are connected below the waterline by a rectangular pontoon frame. At the base of each column, two steel tethers descend to a pile foundation on the seafloor. Each of the eight piles is 8 feet in diameter (2.44 meters) and about 339 feet long (103 meters). They were driven about 319 feet (95 meters) into the ocean floor.

Deep Sea Technology

It is amazing that people have figured out how to find, drill and produce oil from floating platforms in water that is nearly one mile deep - where the oil reservoir is three miles below the seabed!

Author: Hobart M. King, Ph.D.

| More Oil |

|

Horizontal Drilling |

|

Oil and Gas Rights |

|

Shale Gas Resources |

|

Gifts That Rock |

|

What is LNG? |

|

The Doorway to Hell |

|

Natural Gas Investing |

|

Helium |

Find Other Topics on Geology.com:

|

| ||

|

| ||

|

| ||

|

|