Home » Oil and Gas » Hydraulic Fracturing

Hydraulic Fracturing of Oil & Gas Wells Drilled in Shale

Hydraulic fracturing and horizontal drilling have turned unproductive shales into the largest natural gas fields in the world.

Article by: Hobart M. King, PhD

Pumps and diesel engines ready for the frac: Photo of a hydraulic fracturing operation being conducted at a drilling pad in the Marcellus Shale gas play of southwestern Pennsylvania. An enormous assemblage of pumps, diesel engines, water trucks, sand mixers, and plumbing fixtures is in place for the frac. Image by Doug Duncan, USGS.

What is Hydraulic Fracturing?

Hydraulic fracturing is a procedure that can increase the flow of oil or gas from a well. It is done by pumping liquids down a well into subsurface rock units under pressures that are high enough to fracture the rock. The goal is to create a network of interconnected fractures that will serve as pore spaces for the movement of oil and natural gas to the well bore.

Hydraulic fracturing combined with horizontal drilling has turned previously unproductive organic-rich shales into the largest natural gas fields in the world. The Marcellus Shale, Utica Shale, Barnett Shale, Eagle Ford Shale, and Bakken Formation are examples of previously unproductive rock units that have been converted into fantastic gas or oil fields by hydraulic fracturing.

How Long Has Hydraulic Fracturing Been Used?

The first use of hydraulic fracturing to stimulate oil and natural gas wells in the United States was done over 60 years ago. Haliburton Oil Well Cementing Company was issued a patent for the procedure in 1949. The method successfully increased well production rates and the practice quickly spread. It is now used throughout the world in thousands of wells every year. Our gasoline, heating fuel, natural gas and other products made from petroleum products would cost a lot more if hydraulic fracturing had not been invented.

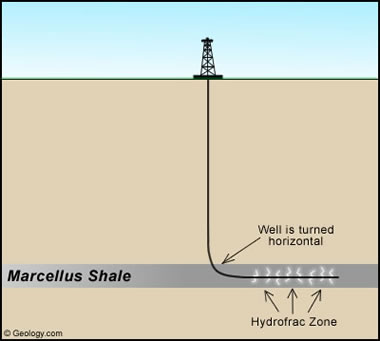

Horizontal drilling and hydraulic fracturing: Simplified diagram of a natural gas well that has been constructed with horizontal drilling through the Marcellus Shale and hydraulic fracturing on the horizontal portion of the well.

Drilling pad ready for hydraulic fracturing: Another photo of a drill pad on frac day in the Marcellus Shale gas play of southwestern Pennsylvania. Photo by Doug Duncan, USGS.

Successful Use of Hydraulic Fracturing in Shale

In the early 1990s, Mitchell Energy began using hydraulic fracturing to stimulate the production of natural gas from wells drilled into the Barnett Shale of Texas. The Barnett Shale contained enormous amounts of natural gas; however, the Barnett rarely produced natural gas in commercial quantities.

Mitchell Energy realized that gas in the Barnett Shale was trapped in tiny pore spaces that were not interconnected. The rock had pore space but lacked permeability. Wells drilled through the Barnett Shale would usually have a show of gas but not enough gas for commercial production. Mitchell Energy solved this problem by hydraulic fracturing the Barnett Shale to create a network of interconnected pore spaces that enabled a flow of natural gas to the well.

Unfortunately, many of the fractures produced by the hydraulic fracturing process snapped closed when the pumps were turned off. The Barnett Shale was so deeply buried that confining pressure closed the new fractures. This problem was solved by adding sand to the fracturing fluid. When the rock fractured, the rush of water into the newly-opened pore space would carry sand grains deep into the rock unit. When the water pressure was reduced, the sand grains "propped" the fracture open and allowed a flow of natural gas through the fractures and into the well bore. Today there are a variety of natural and synthetic products that are sold under the name of "frac sand."

Mitchell Energy further improved the yield of their wells by drilling them horizontally through the Barnett Shale. Vertical wells were started at the surface, steered to a horizontal orientation and driven through the Barnett Shale for thousands of feet. This multiplied the length of the pay zone in the well. If a rock unit was 100 feet thick, it would be have a pay zone of 100 feet in a vertical well. However, if the well was steered horizontal and stayed horizontal for 5000 feet through the target formation, then the length of the pay zone was fifty times longer than the pay zone of a vertical well.

Mitchell Energy used hydraulic fracturing and horizontal drilling to multiply the productivity of Barnett Shale wells. In fact, many of their highly successful wells would have been failures if they were vertical wells without hydraulic fracturing.

Perforation gun: Unused and spent perforating guns used in oil and gas drilling and hydraulic fracturing. The pipe on the bottom shows holes created by the explosive charges mounted inside the pipe. Photo by Bill Cunningham, USGS.

Hydraulic Fracturing in Other Shale Plays

As others learned of Mitchell Energy's success in the Barnett Shale of Texas, the methods of horizontal drilling and hydraulic fracturing were tried in other organic-rich shales. These methods quickly succeeded in the Haynesville Shale and Fayetteville Shale of Louisiana, Texas and Arkansas - then in the Marcellus Shale in the Appalachian Basin. The methods worked in many other shales and are now being used to develop organic-rich shales in many parts of the world.

Hydraulic fracturing has also enabled production of natural gas liquids and oil from many wells. Rock units such as the Bakken Shale of North Dakota and the Niobrara Shale of Colorado, Kansas, Nebraska and Wyoming are now yielding significant amounts of oil from hydraulic fracturing.

Frac water containment pond: A water impoundment at a drill pad in the Fayetteville Shale gas play of Arkansas. Lined ponds like this are used for frac water storage at drilling sites in all of the natural gas plays. Photo by Bill Cunningham, USGS.

Fracturing Fluids

Water is the driving fluid used in the hydraulic fracturing process. Depending upon the characteristics of the well and the rock being fractured, a few million gallons of water can be required to complete a hydraulic fracturing job.

When the water is pumped into the well, the entire length of the well is not pressurized. Instead, plugs are inserted to isolate the portion of well where the fractures are desired. Only this section of the well receives the full force of pumping. As pressure builds up in this portion of the well, water opens fractures, and the driving pressure extends the fractures deep into the rock unit. When pumping stops these fractures quickly snap closed, and the water used to open them is pushed back into the borehole, back up the well and is collected at the surface. The water returned to the surface is a mixture of the water injected and pore water that has been trapped in the rock unit for millions of years. The pore water is usually a brine with significant amounts of dissolved solids.

Chemicals are often added to the water used in hydraulic fracturing. These additives serve a variety of purposes. Some thicken the water into a gel that is more effective at opening fractures and carrying proppants deep into the rock unit. Other chemicals are added to: reduce friction, keep rock debris suspended in the liquid, prevent corrosion of equipment, kill bacteria, control pH and other functions.

Most companies have been resistant to revealing the composition of their hydraulic fracturing fluids. They believe that this information should be kept private to protect their competitive research. However, regulators are starting to demand the information, and some companies are starting to share the information voluntarily.

Frac sand: Fine-grained silica sand is mixed with chemicals and water before being pumped into rock formations to prevent the newly created artificial fractures from closing after hydraulic fracturing is completed. Photo by Bill Cunningham, USGS.

Proppants

A variety of proppants are used in hydraulic fracturing. These are small crush-resistant particles that are carried into the fractures by the hydraulic fracturing fluid. When the pumps are turned off and the fractures collapse, these crush-resistant particles hold the fracture open, creating pore space through which natural gas can travel to the well.

Frac sand is the proppant most commonly used today but aluminum beads, ceramic beads, sintered bauxite and other materials have also been used. Over one million pounds of proppants can be used while fracturing a single well.

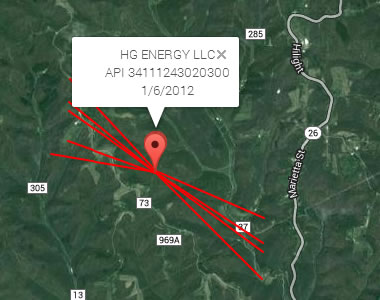

Satellite image view of horizontal wells: A satellite view of a Utica Shale drilling site where nine horizontal wells have been constructed and stimulated with hydraulic fracturing.

Environmental Concerns

There are a number of environmental concerns related to hydraulic fracturing. These include:

1) Fractures produced in the well might extend directly into shallow rock units that are used for drinking water supplies. Or, fractures produced in the well might communicate with natural fractures that extend into shallow rock units that are used for drinking water supplies.

2) The casing of a well might fail and allow fluids to escape into shallow rock units used for drinking water supplies.

3) Accidental spills of hydraulic fracturing fluids or fluids expelled during a fracturing job might seep into the ground or contaminate surface water.

Production Benefits

Hydraulic fracturing can significantly increase the yield of a well. When it is combined with horizontal drilling, unprofitable rock formations are often converted into productive natural gas fields. The technique is largely responsible for development of the Barnett Shale, Haynesville Shale, Fayetteville Shale, and Marcellus Shale gas fields. It can also liberate oil from tight rock units as has been done with the Bakken Shale and Niobrara Shale.

The hydraulic fracturing process and the chemicals used with it cause the greatest amount of concern to environmental advocates who watch the natural gas industry. A regulatory environment is needed which will allow these techniques to be employed and provide environmental safeguards to protect water supplies and people who live in the areas where drilling occurs.

| More Oil |

|

The Doorway to Hell |

|

Oil Sands |

|

Shale Gas Resources |

|

Gifts That Rock |

|

Horizontal Drilling |

|

Oil and Gas Rights |

|

Natural Gas Prices |

|

Oil Shale |

Find Other Topics on Geology.com:

|

| ||

|

| ||

|

| ||

|

|