Home » Oil and Gas » What is Frac Sand?

What is Frac Sand?

This special sand is one of the keys to producing oil and natural gas from tight shale formations

Article by: Hobart M. King, PhD, RPG

Frac sand: Close-up view of frac sand (on the right) and a typical sand of similar grain size (on the left). Notice how the frac sand has a more uniform grain size, nicely rounded grain shapes, and a uniform composition. It is also a very tough material that can resist compressive forces of up to several tons per square inch. Grains in this image are about 0.50 millimeter in size. Photo copyright iStockphoto / BanksPhotos.

Frac sand production: This chart illustrates the amount of natural industrial sand that has been used as proppant in the hydraulic fracturing process. It does not include man-made materials that have been used as a proppant (such as ceramic beads, aluminum beads, or sintered bauxite. Data is from the United States Geological Survey Minerals Yearbooks and the United States Geological Survey Mineral Commodity Summaries, 2005-2020.

What Is Frac Sand?

"Frac sand" is a high-purity quartz sand with very durable and very round grains. It is a crush-resistant material produced for use by the petroleum industry. It is used in the hydraulic fracturing process (known as "fracking") to produce petroleum fluids, such as oil, natural gas, and natural gas liquids from rock units that lack adequate pore space for these fluids to flow to a well.

Most frac sand is a natural material made from high-purity sandstone. Alternative products are ceramic beads made from sintered bauxite or small metal beads made from aluminum.

The demand for frac sand exploded in 2010, when the use of hydraulic fracturing became the standard method of producing oil and gas from tight rock formations such as the Marcellus Shale and Utica Shale of the Appalachian Basin. Today, thousands of oil and natural gas wells are stimulated every year using horizontal drilling and hydraulic fracturing.

A hydraulic fracturing job on one well can require a few thousand tons of sand. This surge of specialized drilling has created a billion-dollar frac sand industry in a very short time. Between 2005 and 2014, the amount of frac sand used by the oil and gas industry has increased dramatically.

Millions of tons of frac sand are now used every year. That trend will continue as long as the hydraulic fracturing process is used to stimulate wells, or until man-made proppants become more effective or less costly substitutes.

Frac sand video: Video by U.S. Silica demonstrating the characteristics of a high-quality frac sand.

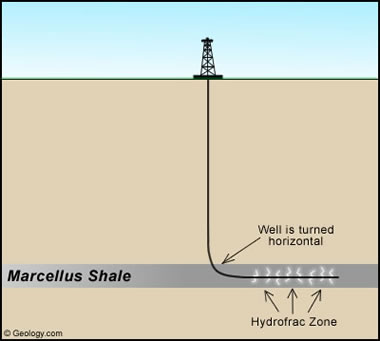

How is Frac Sand Used?

Some subsurface rock units such as organic shale contain large amounts of oil, natural gas, or natural gas liquids that will not flow freely to a well. They will not flow to a well because the rock unit either lacks permeability (interconnected pore spaces), or the pore spaces in the rock are so small that these fluids cannot flow through them.

The hydraulic fracturing process solves this problem by generating fractures in the rock. This is done by drilling a well into the rock, sealing the portion of the well in the petroleum-bearing zone, and pumping water under high pressure into that portion of the well. This water is generally treated with chemicals and thickeners such as guar gum to create a viscous gel. This gel facilitates the water's ability to carry grains of frac sand in suspension.

Large pumps at Earth's surface increase the water pressure in the sealed portion of the well until it is high enough to exceed the breaking point of the surrounding rocks. When their breaking point is reached, they fracture suddenly and water rushes rapidly into the fractures, inflating them and extending them deeper into the rock. Billions of sand grains are carried deep into the fractures by this sudden rush of water. A few thousand tons of frac sand can be required to stimulate a single well.

Hydraulic fracturing: Simplified diagram of a natural gas well that has been constructed with horizontal drilling to increase the length of penetration through the Marcellus Shale. Hydraulic fracturing is typically done in the horizontal portion of the well to stimulate a flow of gas from the shale. This well configuration is used in shale plays of the United States.

Frac Sand as a "Proppant"

When the pumps are turned off, the fractures deflate but do not close completely - because they are propped open by billions of grains of frac sand. This only occurs if enough sand grains to resist the force of the closing fractures have been delivered into the rock.

The new fractures in the rock, propped open by the durable sand grains, form a network of pore space that allows petroleum fluids to flow out of the rock and into the well. Frac sand is known as a "proppant" because it "props" the fractures open.

Other materials that have been used as a proppant include ceramic beads, aluminum beads, and sintered bauxite. Frac sand generally delivers the highest level of performance, and it is currently the proppant most frequently used by the petroleum industry.

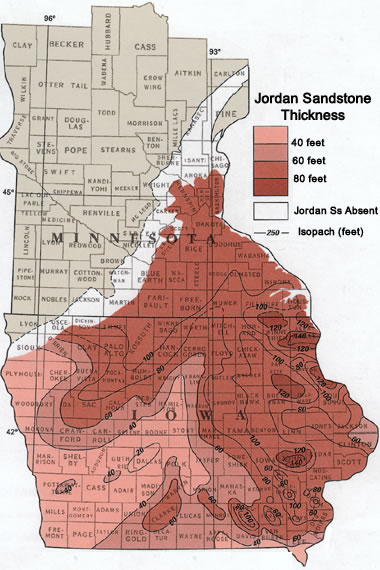

Jordan Sandstone map: Many of the rock units that are currently being mined for frac sand are also aquifers. This makes groundwater research publications, such as the groundwater atlas series of the United States Geological Survey, valuable prospecting documents for determining the presence, thickness, and structure of sandstone rock units. This map is from the Ground Water Atlas of the United States for Iowa, Michigan, Minnesota, and Wisconsin. It shows the geographic extent and thickness of the Jordan Sandstone in Minnesota and Iowa. Similar maps have been published in this series for other sandstone rock units and other geographic areas.

What Type of Sand?

Petroleum industry proppants must meet very demanding specifications. The characteristics of a high-quality frac sand include:

- high-purity silica sand

- grain size perfectly matched to job requirements

- spherical shape that enables it to be carried in hydraulic fracturing fluid with minimal turbulence

- durability to resist crushing forces of closing fractures

Frac sand is produced in a range of sizes from as small as 0.1 millimeter in diameter to over 2 millimeters in diameter, depending upon customer specifications. Most of the frac sand consumed is between 0.4 and 0.8 millimeters in size.

Rock units such as the St. Peter Sandstone, Jordan Sandstone, Oil Creek Sandstone, and Hickory Sandstone have been potential sources of frac sand material. These rock units are composed of quartz grains that have been through multiple cycles of weathering and erosion. That long history has removed almost all mineral grains other than quartz and produced grains with very round shapes. This is why sand dredged from rivers, excavated from terraces, or removed from beaches is unlikely to produce a good product.

Where these rock units are produced, they are usually soft, poorly cemented, and sometimes lightly weathered. This allows them to be excavated and crushed with minimal damage to the quartz grains. High-purity sand from areas such as the Appalachians is often not suitable for frac sand because it has been subjected to tectonic forces which have deformed the rock and weakened the sand grains.

Frac sand mine in Wisconsin: Aerial view of a frac sand mining operation in Wisconsin. Frac sand is a highly specialized product that can only be produced from a small number of sand deposits. Photo copyright iStockphoto / BanksPhotos.

Frac sand processing facility: Aerial view of a frac sand processing facility in Wisconsin. Photo copyright iStockphoto / BanksPhotos.

Frac Sand Processing Plants

Frac sand is not used straight from the ground. It requires processing to optimize its performance. After mining it is taken to a processing plant. There it is washed to remove fine particles.

After washing, the sand is stacked in piles to allow the wash water to drain off. This operation is done outdoors and is restricted to times of the year when temperatures are above freezing. After the sand is drained, it is placed in an air dryer to remove all moisture. The dry grains are then screened to obtain specific size fractions for different customers.

Sand that is not suitable for fracking is separated and sold for other uses. Some frac sand might be resin coated to improve its performance in the fracking operation. This material will be sold as a premium product. After processing, most sand is loaded directly into train cars for rail delivery.

Some processing plants are located at the mine site. However, processing plants are very expensive to build and are sometimes shared by multiple mines. These are centrally located to several mines, and the sand is delivered by truck, train, or conveyor.

Where is Frac Sand Produced and Used?

A few years ago producers in Wisconsin and Texas were supplying much of the frac sand used by the oil and gas industry. However, a huge spike in demand caused by the natural gas and shale oil boom has motivated many companies to provide this product. Many of these companies are in the central part of the United States where the St. Peter Sandstone and similar rock units are close to the surface and easily excavated.

These areas are also where tectonic forces have not caused severe folding of the rock units and weakened the sand grains. The prime area is in the midwestern states (Illinois, Indiana, Iowa, Kansas, Kentucky, Minnesota, Michigan, Missouri, Nebraska, and Wisconsin).

Most of the high-purity silica sands in the United States have been known for decades. They have been used for glass making and metallurgical uses. The current search for frac sand is not about "discovering new sources of sand" - it is instead about determining which sources produce superior materials.

Frac sand is used to produce natural gas, natural gas liquids, and oil from shales and other tight rocks where hydraulic fracturing is required. These include: the Marcellus Shale, Utica Shale, Bakken Formation, Haynesville Shale, Fayetteville Shale, Eagle Ford Shale, Barnett Shale, and many other shale plays throughout the United States.

St. Peter Sandstone: A photo of the St. Peter Sandstone capped by the Joachim Dolomite taken near Pacific, Missouri. Public domain image by Kbh3rd.

Frac Sand Sources and Prices

The demand for frac sand in North America has risen sharply in the last few years in response to numerous shale plays developing in many parts of the United States, Canada, and Mexico. The United States Geological Survey reports the source of this production:

The Ordovician St. Peter Sandstone in the Midwest is a primary source of silica sand for many end uses and is a major source of frac sand as well. Mined in five States, frac sand from the St. Peter Sandstone is within reasonable transport distance to numerous underground shale formations producing natural gas.

Reported average prices for frac sand in the U.S. Geological Survey Minerals Yearbook and Mineral Commodity Summary are volatile. Between 2016 and 2018 the price ranged from $35 to $56 per ton - at the mine site. Delivered prices can be enormously higher depending upon the distance the sand has to be transported and the number of times that it must be handled on the way.

| Frac Sand Information |

|

[1] The Facts of Frac: Mark Zdunczyk, article from Drilling Minerals, January 2007.

[2] $and Dollars - Mining Frac Sand in the River Valley: Reggie McLeod, Big River Magazine, July-August 2011. [3] Oil Companies Drawn to Frac Sand: Isabel Ordonez, Dow Jones Newswires article on Rigzone.com, May 2012. [4] Silica Statistics and Information: United States Geological Survey, Minerals Yearbooks and Mineral Commodity Summaries from 2005 to 2020. [5] Ground Water Atlas of the United States, United States Geological Survey, Hydrologic Investigations Atlas Series, published 1992 through 2000. |

Sintered Bauxite Proppants

Powdered bauxite can be fused into tiny beads at very high temperatures. These beads have a very high crush resistance, and that makes them suitable for use as a proppant. The specific gravity of the beads and their size can be matched to the viscosity of the hydraulic fracturing fluid and to the size of fractures that are expected to develop in the rock.

Manufactured proppants provide a wide selection of grain size and specific gravity compared to the natural proppant known as frac sand. Frac sand is currently used instead of manufactured proppants because it has a cost and transportation advantage.

| More Oil |

|

The Doorway to Hell |

|

Oil Sands |

|

Shale Gas Resources |

|

Gifts That Rock |

|

Horizontal Drilling |

|

Oil and Gas Rights |

|

Natural Gas Prices |

|

Oil Shale |

Find Other Topics on Geology.com:

|

| ||

|

| ||

|

| ||

|

|